Unveiling the Strength of Amorphous Silicon Carbide for Industry Scalability

The landscape of material science is undergoing a profound transformation as a novel material, amorphous silicon carbide (a-SiC), emerges with properties set to redefine microchip technology's future.

Led by assistant professor Richard Norte at Delft University of Technology, researchers are heralding a new era where the intricacies of vibration isolation become central to advancing the performance of microchip sensors.

Just as the metaverse represents the convergence of humans and machines, the advent of a-SiC marks a convergence of strength and precision at the microscopic level. This breakthrough is not a distant possibility but a current reality, promising to infuse everyday technology with unprecedented sensitivity and durability.

What is Amorphous Silicon Carbide?

At the heart of this revolution is the material's unique amorphous structure. Unlike crystalline counterparts with ordered atomic arrangements, a-SiC boasts a randomly organised lattice that surprisingly endows it with exceptional strength. This paradoxical robustness, characterised by a tensile strength of 10 GigaPascal (GPa), positions a-SiC as a material that defies traditional expectations—comparable to hanging ten medium-sized cars off a duct tape strip before it succumbs to stress.

The Innovation of a-SiC in Microchip Technology

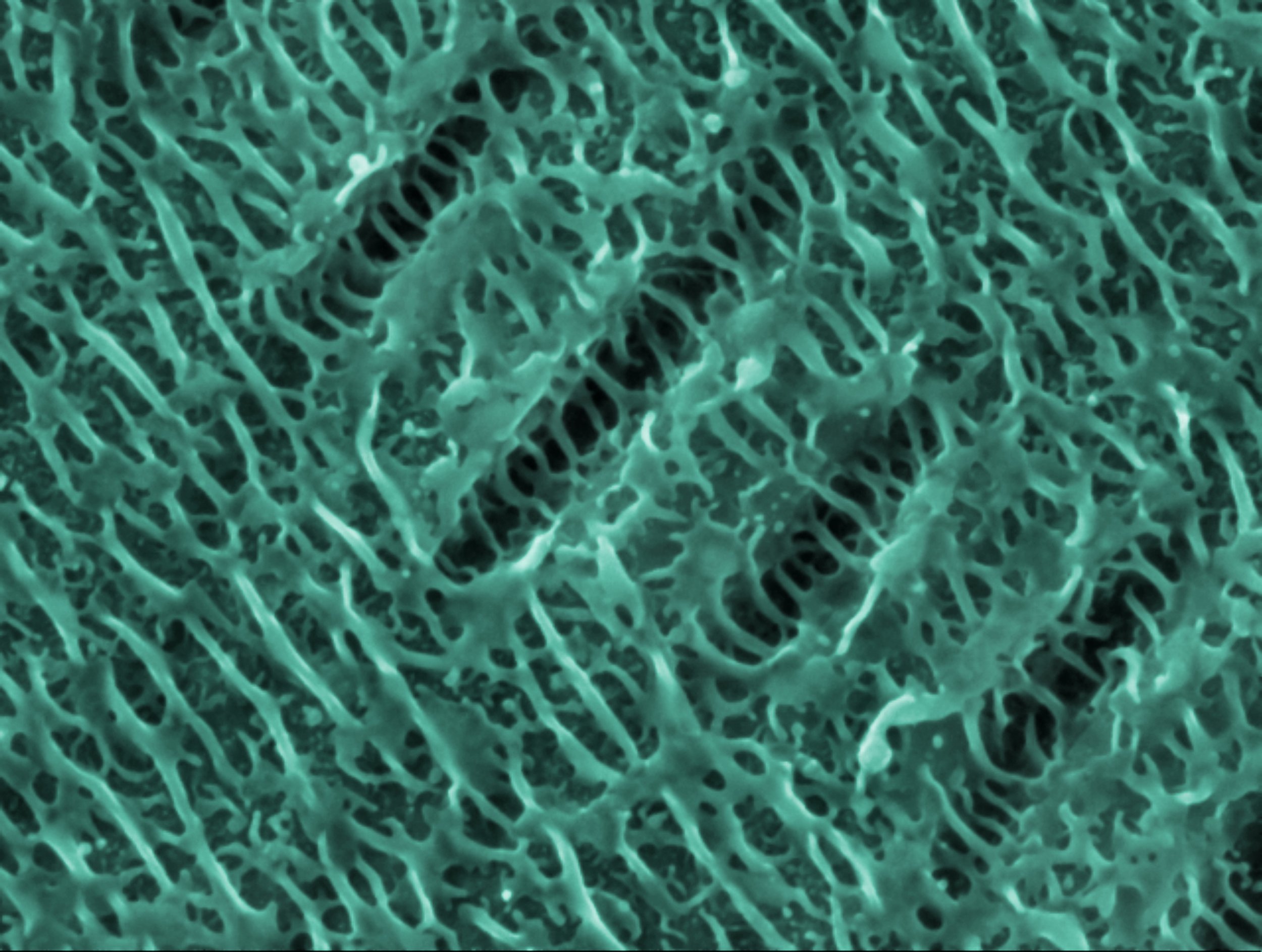

Norte's research, detailed in Advanced Materials, pivots on creating nanostrings from a-SiC, pushing the boundaries of what was previously achievable in microchip sensors. By utilising microchip technology to cultivate and test these nanostructures, the team has not only validated the material's exceptional strength but also its applicability in the most delicate and demanding of technological contexts.

These advancements in a-SiC sensors represent a quantum leap towards microchips that can detect the subtlest vibrations, paving the way for breakthroughs in fields as diverse as space exploration and DNA sequencing. The implications are profound, positioning such sensors as pivotal components in technologies that demand ultra-sensitive detection capabilities.

Silicon Carbide Market Size

The future of amorphous silicon carbide (a-SiC) in the semiconductor market looks robust, with the industry poised for significant growth. In 2021, the need for silicon carbide semiconductor devices already had a valuation of USD 1.52 billion and is forecasted to surge at a compound annual growth rate (CAGR) of 23.8% from 2022 to 2030. This growth points to the increasing adoption and scalability of a-SiC across various industrial applications.

Highlighting the material’s potential, industry reports confirm that "Silicon Carbide (SiC) semiconductor devices have emerged as the most viable devices for next-generation, low-cost semiconductors due to their superior material properties." This assertion cements a-SiC’s status as an integral player in the evolution of semiconductor technology, where its unique properties are essential for developing more efficient and economical devices.

Industry Pioneers and the Future of a-SiC

The foundation laid by the Delft University of Technology is just the genesis of what is set to become a pivotal area of research and application. This burgeoning interest in silicon carbide technology has captured the imagination of the industry, with both fledgling startups and established tech giants recognising its transformative potential.

As this dynamic field expands, it's clear that the exploration and integration of a-SiC are paving the way for advancements that scale from intricate electronic components to grand industrial solutions.

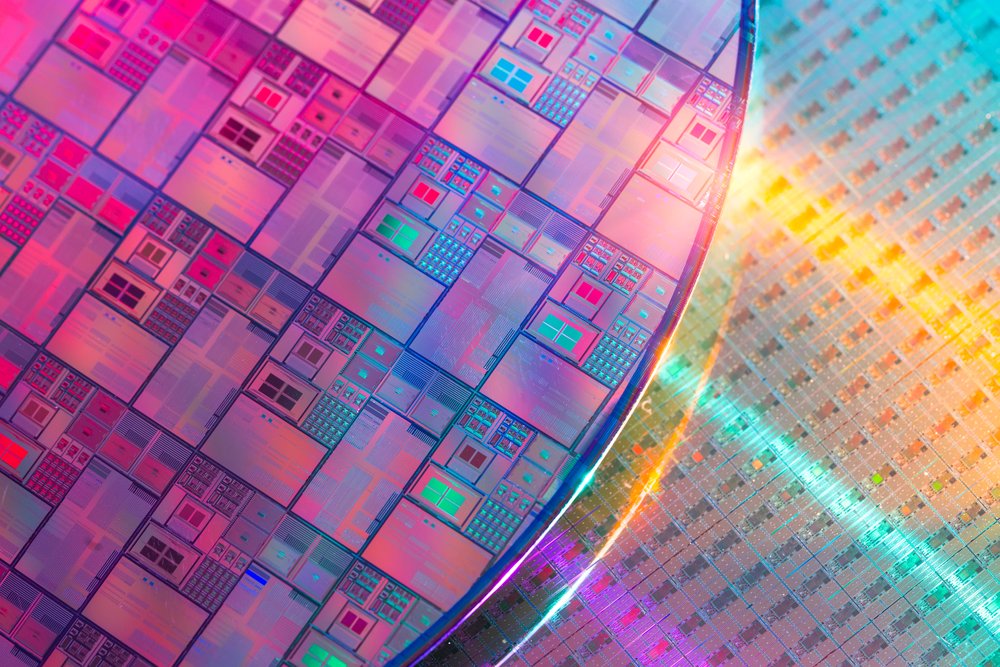

Pallidus, based in Houston, United States, is a producer of Silicon Carbide, integral to wafer production. They generate particles sized from 0.2 to 1 micron through a proprietary process. Their M-SiC silicon carbide, acclaimed for its 99.9999% purity, aims to escalate solar wafer efficiency and diminish system costs. The company's innovative strides have attracted significant investment, amassing over $94 million in funding.

On the other side of the globe, Nanjing, China-based Zinsight is carving a niche in producing electric drive systems and silicon carbide semiconductor devices. The firm, with an investment backing of over $13 million, is dedicated to the progression of electric machine drives and systems empowered by silicon carbide technology. Zinsight's SiCTeX series motor drives represent their latest innovation, engineered for diverse applications such as FCV air compressors, microturbine generators, centrifugal compressors, and electric propulsion systems in aircraft and specialised vehicles.

Conclusion

The unveiling of amorphous silicon carbide is a testament to human ingenuity, a material that blends randomness with precision to open new frontiers in microchip technology. As we stand on the brink of this new era, the scope for innovation is boundless, and the commitment to explore and expand the applications of a-SiC is steadfast.

COMPANIES TO WATCH:

Pallidus, Zinsight, Graphensic,

Author:

Arnold Kristoff

Content Producer and Writer