Advancing Heat Management in Nanodevices Through Silicon Dioxide Coatings

Researchers in Japan are making strides in the field of nanotechnology by addressing the critical issue of overheating in nanodevices.

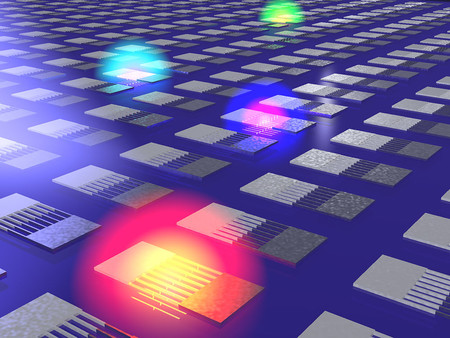

Through innovative experimentation, they've discovered that applying a minuscule layer of silicon dioxide to micro-sized silicon structures can substantially boost the rate at which heat is dissipated. This breakthrough could pave the way for the development of smaller, more affordable electronic devices that can accommodate a higher density of microcircuits.

As consumer electronics continue to shrink while their processing power increases, managing waste heat from these microcircuits has become a significant challenge. Efficient heat dissipation is crucial for the performance and longevity of electronic components, particularly in scientific instruments and nanoscale machines where localised heat must be carefully managed to prevent damage.

One method of cooling involves radiating heat as electromagnetic waves, similar to how the sun’s energy travels through space to reach Earth. However, this process can often be too slow to effectively protect the performance of densely packed integrated electronic circuits. Therefore, new approaches are necessary to enhance heat transmission in next-generation devices.

A recent study published in the journal Physical Review Letters by researchers from the Institute of Industrial Science at The University of Tokyo offers a promising solution. The team demonstrated that the rate of radiative heat transfer between two micro-scale silicon plates, separated by a minuscule gap, can be doubled by using a coating of silicon dioxide. This coating creates a coupling between the thermal vibrations at the surface of the silicon plates, known as phonons, and the photons, which constitute the radiation.

Lead author Saeko Tachikawa explained, “We were able to show both theoretically and experimentally how electromagnetic waves were excited at the interface of the oxide layer that enhanced the rate of heat transfer.” This enhancement is significant because the small size of the silicon dioxide layers, relative to the wavelengths of the electromagnetic energy, allows the energy to be carried efficiently without loss.

The ability of the silicon dioxide layer to surpass the normal limits of heat transfer and cool the device more quickly is a key finding. Given that current microelectronics predominantly use silicon, integrating these findings into future semiconductor devices should be straightforward. This innovation could lead to more efficient heat dissipation strategies, benefiting the semiconductor industry and related fields such as nanotechnology manufacturing.

Senior author Masahiro Nomura emphasized the broader implications of their work, stating, “Our work provides insight into possible heat dissipation management strategies in the semiconductor industry, along with various other related fields such as nanotech manufacturing.” This research not only offers practical applications but also contributes to a deeper understanding of heat transfer at the nanoscale, an area that remains an active topic of investigation.

The study's findings have far-reaching potential, given the increasing demand for compact and powerful electronic devices. Efficient heat management is essential to prevent overheating, which can degrade performance and reduce the lifespan of electronic components. The innovative use of silicon dioxide coatings could revolutionize how heat is managed in microelectronics, leading to more robust and reliable devices.

Furthermore, the fundamental insights gained from this research into the interaction between phonons and photons at the nanoscale are invaluable. By understanding these mechanisms better, scientists can develop more advanced materials and technologies that leverage these principles for enhanced performance. This study is a significant step forward in the quest to manage heat in ever-smaller electronic components, ensuring that future devices can continue to evolve in both power and efficiency.

In summary, the work of the Japanese researchers highlights the importance of innovative approaches to heat dissipation in microelectronics. By utilizing a silicon dioxide coating, they have demonstrated a method to significantly increase the rate of heat transfer, providing a viable solution to a critical problem in the design of next-generation electronic devices. Their findings not only offer practical benefits for the semiconductor industry but also advance our understanding of thermal dynamics at the nanoscale, paving the way for future breakthroughs in nanotechnology and materials science.

Author:

Kate Sivess-Symes

Content Producer and Writer