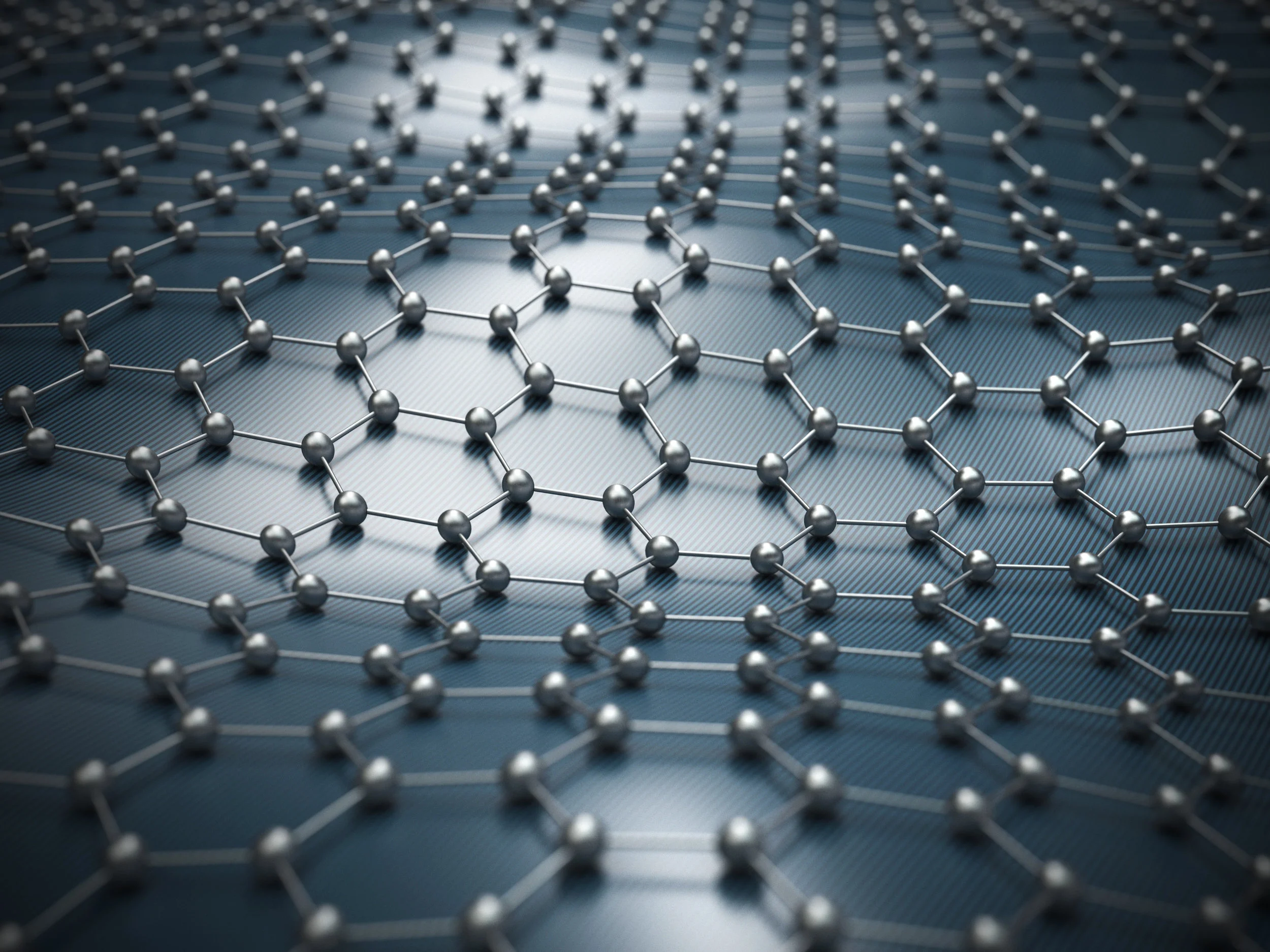

Why Are There Challenges with Graphene Manufacturing?

It’s no secret that there’s challenges associated with large scale graphene manufacturing, anyone in the industry will tell you this. However, whilst there has been a focus of late surrounding graphene, we mustn’t forget that graphene is not alone in these challenges.

Up until recently there were many challenges with commercial scale 3D printing, and let’s not forget the issues surrounding the dispersion and alignment of carbon nanotubes (CNTs)—which have, in recent years, started to be used beneficially in products. In fact, there are always manufacturing challenges, regardless of the material or industry. So, why is there so much of a focus on graphene? Simple, many people make it out to be the material that can solve the shortcomings of any application and the material that can be used to improve efficiencies across almost all scientific and technology sectors—the so-called wonder material. Yet, graphene is still privy to the many challenges that face many manufacturing sectors.

So why are there challenges with graphene manufacturing? First off, there are many types of graphene (even though this is disputed, the general consensus within the industry is now that there are a family of graphenes). Secondly, there are different methods to producing graphene, which leads to very different outcomes. Thirdly, the graphene that is actually usable in a product is different to the raw manufactured product.

So, looking at the first point. There are many different types of graphene, and all of them are good in their own way—some of the higher-layered numbers (but less than 10) are cheaper and are better as an additive, whilst single-layer graphene is more useful for electronics. Unfortunately, the education of graphene to people outside of the graphene industry is not great—be it end-user markets or large corporations in general—and most people who are looking to use it, don’t know what they are buying. So, whilst there may well be a perfectly good type of graphene out there for someone’s application, they may not necessarily choose the right type, and this leads to poor results and a decrease in the market confidence. More effort is being done is this area to better educate decision makers and more end-user products are now being realised, which is starting to increase the confidence in graphene again.

Moving on to the different methods. There are two main methods of producing graphene commercially—chemical vapour deposition (CVD) and exfoliation from graphite. CVD is a bottom-up approach that creates a single layer of graphene on a substrate. Whilst this is arguably the ‘highest-quality’ graphene because it is a single-layer, it is also generally more expensive and can (currently) only be produced in smaller amounts. There are also other issues with removing graphene from the substrate that it forms on, meaning that it often has to be deposited on a customer’s substrate of interest in-house. Therefore, it is not the most scalable, but is ideal for some applications, such as electronics. On the other hand, you have exfoliation methods. These methods cleave graphite into graphene. However, because harsh chemicals, mechanical stress, solar rays, or high temperatures are used to break down the intermolecular bonds in the graphite, the process is a lot more uncontrollable. This often results in products which have a distribution of layers from batch to batch. This is often seen as a lower-quality type of graphene; however, it is much cheaper, can be produced in much greater quantities and is still suitable as an additive in various types of composites/products.

The next point to consider is how graphene is used in a product. Before it is used as an additive, it needs to be functionalised so that it stays stable within the composite matrix. This means that the properties of the usable graphene are different to that of the raw product, so in many ways, the so-called “quality” is not always relevant (because the properties change anyway) and is why the exfoliated graphene has become more usable recently. The same applies for other graphene derivatives such as graphene oxide and reduced graphene oxide which are already partially functionalised.

Overall, there are a few challenges to overcome and iron out, but there are no more than which are faced in any other manufacturing industry. The difference here is that everyone is so expectant for everything to work first time because everyone knows about graphene and knows it potential. People also refer to a lack of standards as well. Whilst there are currently no physical or measurement standards in place, these are being worked on and will take time just like they do for any other material. There are currently ISO terminology standards in place, which many people don’t realise. Again, the expectancy is there for it all to happen straight away because it is graphene, but every material has to go through a long process before all standards are in place. In short, graphene is not really different to any other material, nor are its manufacturing challenges drastically different to the status quo.

Written by Liam Critchley.