Filtering the Water of Tomorrow with Advanced Nanomaterials

While water is more than a necessity for human survival, many of us in temperate climates take for granted the accessibility that we have to water supplies—and fresh, clean water supplies to be more specific.

But it’s not like that in every part of the world, and there are drives to make clean water more accessible to a wider populace—be it by developing new technologies to get water out of the ground or to make existing harmful water more potable for safe human consumption.

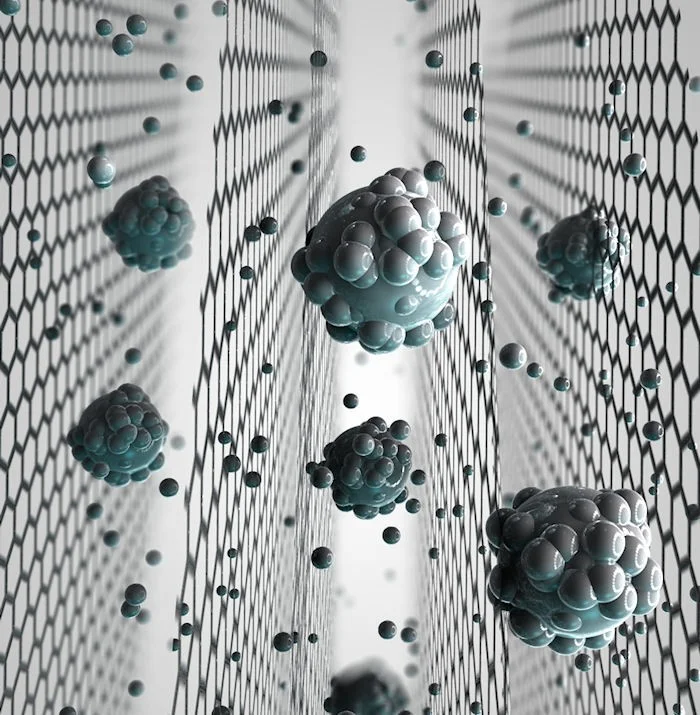

The ultra-thin nature of nanomaterials has been exploited for some time for water filtration applications. There have been many developments from academia, but commercial filters are now on the market (or soon to be on the market) that use nanoscale membranes to filter out harmful substances from a water source.

The small-scale pores in nanoscale membranes mean that a lot more particulate matter and harmful species within a water sample can be removed compared to materials with larger pores and less-active surfaces. This makes nanomaterials the go-to materials for innovating water filters and will soon have wide-reaching implications in providing the clean water of tomorrow.

LG The Biggest Company Adopting Nano Membranes

LG is known for its consumer electronics brands that are present in many homes and workplaces. However, many branches of LG work in other areas, including LG Chem, which has a specific branch tailored to advanced water solutions.

The nanotechnology membranes from LG are called NanoH2O™ and were originally created by a company of the same name before being bought out by LG in 2014. So, not only are they now available from one of the world’s biggest tech companies, but they have also been around commercially for many years.

These membranes are seawater reverse osmosis membranes that use a thin film nanocomposite to filter out salt from water to provide clean drinking water. The membranes have a high salt rejection performance (minimum 99.6%) and use minimal energy, so they have brought down the cost of desalination processes and provided greater access to clean water from saltwater sources.

Carbon-Based Nanomaterials the Most Popular

In the world of nano-filtration, one of the most common materials used is carbon nanomaterials—of which there are numerous forms.

One company using carbon nanomaterials is Carbon Blocktech (CB Tech), which uses a carbon NanomeshTM as a large carbon block filter to purify water and keep it free from contaminants. The technology is proprietary, so the exact structure of the mesh is guarded.

However, CB Tech has several filters available, with the removal of many contaminants being possible with the NanomeshTM technology. Rather than focusing on removing salt or particulate matter, they are more concerned with removing harmful substances (synthetic and natural) from water, including bacteria, viruses, parasitic cysts, pharmaceutical compounds (that have polluted a water source), lead, mercury, Arsenic, and volatile organic chemicals (VOCs).

When carbon nanomaterials are mentioned, the first thought is often graphene, and as it happens, there are also graphene-based filtration systems available commercially. This is an area where a lot has been done academically, but there have only been a few commercial breakthroughs so far.

One company working in this area is Directa Plus, which is an Italian company that uses graphene in many application areas. Directa Plus use their Grafysorber® technology—a layered fabric material that contains graphene and soaks up oil from water.

Unlike other water filtering approaches, the Grafysorber® is being used to clean up water that has been affected by oil spills, as well as being used in water treatment plants for treating water, sludges and emulsions that contain hydrocarbons—recovering the hydrocarbons so that they can be reused rather than go to waste.

Another product that is being developed is a Graphene Flagship funded project called Graphil involving Layer One from Norway and Medica SpA from Italy. This filter uses hollow fibres blended with graphene oxide and polymers as the filtration membrane.

The graphene oxide is used to absorb any contaminants in the water that passes through it, and the filter is being targeted for the removal of harmful contaminants in drinking water, such as antibiotics, pesticides, heavy metals, and the recent hot topic in chemical space of per- and polyfluoroalkyl substances (PFAS).

A Recent Trend of Using Other 2D Materials

While graphene always grabs the headlines in the 2D material space, there are in fact over 100 more 2D materials that have far-reaching applications. This extends to water filtration and recent prototypes are already being showcased that use 2D materials.

One company innovating in this space is the UK company Molymem, which uses molybdenum disulphide (MoS2) ceramic hollow fibre membranes. I’ve personally seen the membrane work through a demonstration at the 2023 Advanced Materials Show, turning dirty water into clean water instantaneously.

Ceramic membranes are becoming more popular in the market due to their longer lifetimes (compared to polymer membranes). As well as being highly resistant to corrosion, these 2D material membranes also have ultra-small pores and high water flux, meaning that many molecules can be filtered out while still achieving a high throughput.

The interesting concept of the Molymem filter is that they are not selling a complete filter itself. They are instead selling the MoS2-ceramic coating as it can be applied to existing membrane filtration technologies.

There are a number of separation applications and industrial settings that are being targeted for these filtration membranes, but in the wastewater space, the key area of interest is in the removal of nitrates and other dissolved organic waste to produce clean water.

This approach from Molymem is set to offer a new approach to nanofiltration because it means that the coatings can be retrofitted to existing systems. This not only offers a way of improving the performance of water filtration membrane but also means that existing membranes do not need to be disposed of (lowering costs and waste).

The most recent development has come from Invicta Water who uses hexagonal boron nitride (h-BN). However, it is not used in its normal form but is rolled up to form boron nanotubes. These boron nanotubes have been used with h-BN crystals to create a rebar-like nanoscale material called NanobarbsTM.

The NanobarbsTM have been around for a number of years from the US company BN Nano. BN Nano have since branched out to found Invicta Water to use the NanobarbsTM in water filtration applications. The target for these filters is the removal and destruction of PFAS chemicals (the destruction occurs when combined with UV light).

Innovations in the membrane world are moving rapidly, and new companies continue to enter the market each year. While this article shows the diversity on offer for nanotechnology in water filter membranes, it’s entirely possible that the commercial landscape could look very different in just a few years’ time.

Written by Liam Critchley