Developing Sustainable Epoxy Composites by Blending Cellulose Nanofibers and Pineapple Leaf Fibers

Scientists from Thailand, France and Singapore have conducted groundbreaking research using both tiny cellulose nanofibers (CNF) and long pineapple leaf fibers (PALF) to create stronger materials. They added varying amounts of CNF to epoxy and found that 1% CNF greatly increased impact strength. PALF-epoxy composites showed significant flexibility and strength improvements. Combining CNF and PALF resulted in a remarkable increase in impact strength. The findings could revolutionize stronger material development.

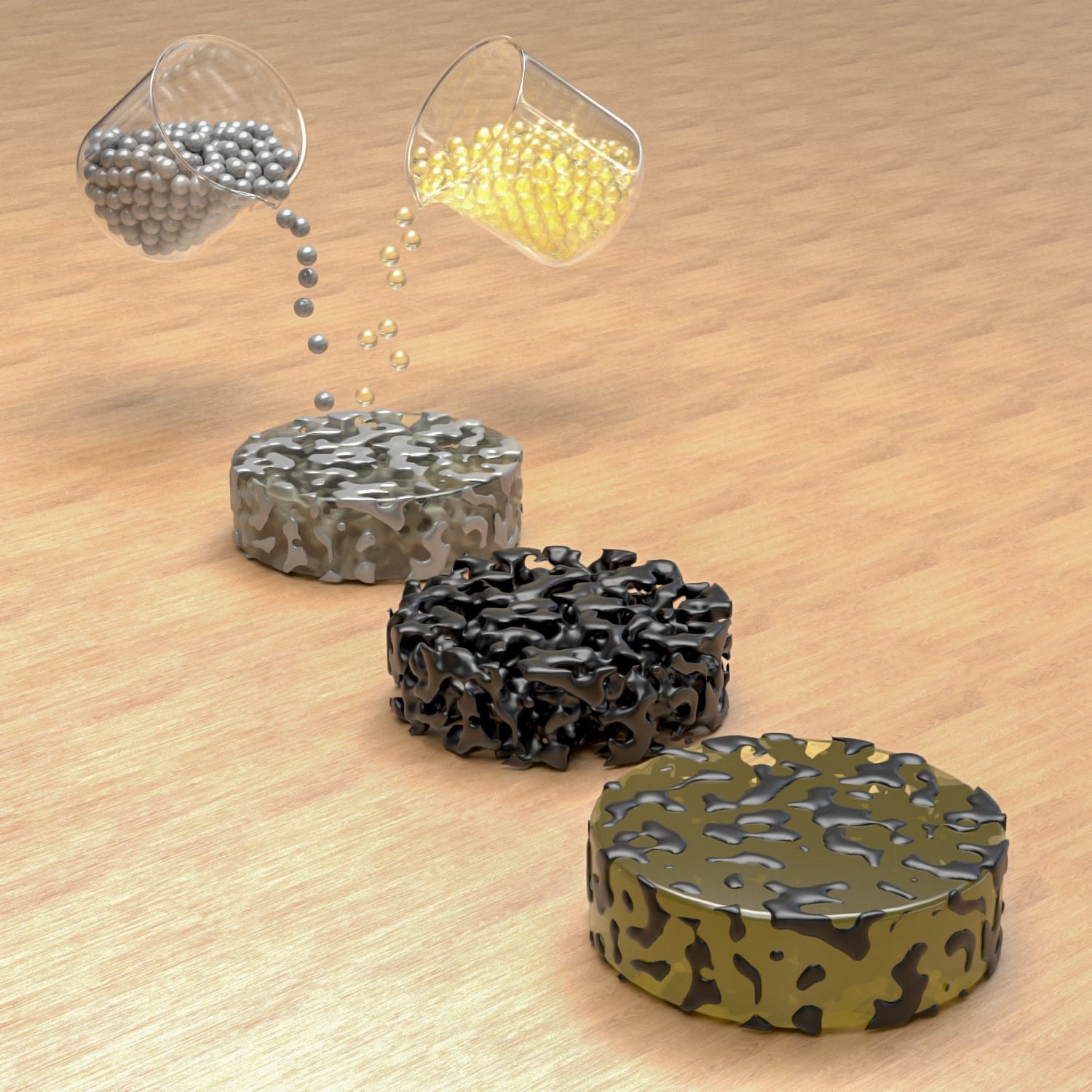

In this new research, published in Nanomaterials, the scientists delved into the world of incredibly tiny fibers known as cellulose nanofibers (CNF) to see how they could make materials stronger. They focused on creating composites using long fibers from pineapple leaves (PALF) and a material called epoxy. To keep things consistent, they always used 20% PALF in the mix, but they varied the amount of CNF at 1%, 3%, and 5% of the epoxy mixture. The composites were carefully assembled by layering the materials by hand.

To see the impact of different combinations, they compared composites reinforced with only CNF, only PALF, and a mixture of both CNF and PALF. Surprisingly, adding these tiny CNF fibers to the epoxy had very little effect on its flexibility and strength. However, when they added just 1% CNF, the impact strength of the epoxy skyrocketed to approximately 115% compared to using epoxy alone. Also, as they increased the amount of CNF to 3% and 5%, the impact strength declined and became similar to that of using epoxy alone.

To investigate further, they examined the broken surfaces of the composites under a powerful microscope. They discovered that as the composites broke, the surface changed from being smooth to much rougher.

The really exciting part arrived when they used epoxy with 20% PALF: both the flexibility and strength experienced a remarkable increase. The flexibility improved by about 300%, while the strength increased by an astonishing 240% compared to using epoxy alone. But hold on, the impact strength of this composite material surged to an incredible 700% compared to using neat epoxy.

When they combined CNF and PALF in the composites, the researchers did not observe significant changes in flexibility and strength compared to using PALF alone. However, there was a notable improvement in impact strength. When they used epoxy with just 1% CNF, the impact strength spiked to around 220% compared to using 20% PALF epoxy, or a mind-blowing 1520% compared to using neat epoxy alone. This result clearly shows that the remarkable increase in impact strength was achieved through the combined effect of CNF and PALF.