Growing the perfect diamond: Simulations reveal interesting geometric patterns

In today's societies, the word "diamond" brings to mind a series of images. It entails stories of strength, wealth, and status. But strip away these associations, and the scientific uses of the material are revealed. Diamonds are transparent, extremely rigid, and don't pose any danger to living tissue. Recently, researchers have started growing ultra-thin polycrystalline diamond films in laboratories. These films, which have many of the properties of diamond gems, could have a number of biomedical and sensor applications. Furthermore, as they are made from carbon, they don't require any expensive or difficult-to-obtain materials.

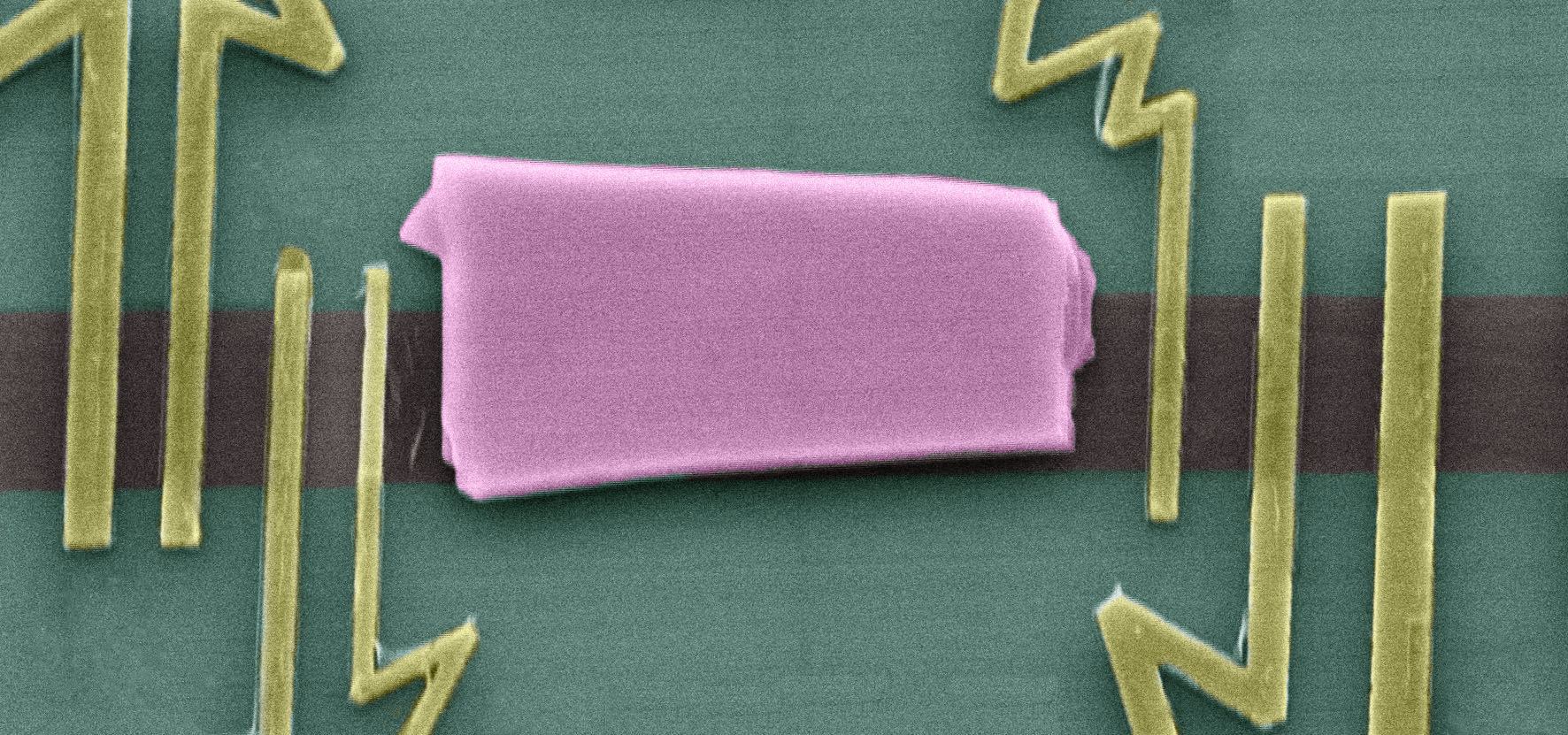

Staff scientist Dr. Stoffel Janssens, from the Mechanics and Materials Unit at the Okinawa Institute of Science and Technology Graduate University (OIST), has simulated the growth of both porous and closed polycrystalline diamond films. Porous diamond films—those with holes scattered throughout the film—could one day be used as platforms for growing neurons and other cells. The simulations were a success, revealing interesting geometric structures within the films, and resulting in a publication in Acta Materialia.

"The simulations have given us a promising view of what we might be able to do in our lab," explained Dr. Janssens. "Porous films currently require complicated techniques to make. We want to be able to create them in a simple and cost-effective way. The simulations have shed light on how long we should grow the films, how large the grains should be, and what we can expect from the results."

To grow polycrystalline diamond films, nano-diamond grains are seeded onto a substrate. In the right conditions, these grains will grow into columnar diamond crystallites that then expand to connect with one another. Over time, these connections strengthen, resulting in a robust material. The two-dimensional simulations allowed Dr. Janssens and his collaborators to observe the detailed consequences of varying the grain size and the initial grain distribution. They found that as a diamond film grows, the grain boundaries that form between the grains create a well-known diagram.

"It's called the Voronoi diagram," Dr. Janssens explained. "It's known to researchers across many different areas of science and engineering—from biologists modeling cellular and bone structures to epidemiologists looking to identify the source of an infection to ecologists studying the growth patterns of forest canopy."

When the researchers changed the grain density, different variations of the diagram emerged. The simulations show that a high initial density of grains leads to a diagram that resembles a honeycomb pattern with pores that are uniformly distributed across the film, whereas a lower initial density of grains leads to pore distributions that are less uniform.

Dr. Janssens also examined the topological transitions that occur at different stages during the growth of a film. The first notable transition occurs when all the grains are connected, forming a porous film. The second notable transition occurs when the grains are strongly connected, forming a closed film without any pinholes. Building on their simulations, the researchers investigated the survival rate of the pinholes and explored strategies for minimizing the chance of pinholes being present in a final closed film.

"The simulations of polycrystalline diamond films contribute to the field of continuum percolation theory," explained Prof. Eliot Fried, Principle Investigator of OIST's Mechanics and Materials Unit. "Apart from providing practical insights that should contribute to the efficient growth of these films in a laboratory setting, this research has enhanced our understanding of underlying topological and geometrical issues related to the growth of polycrystalline films of diamond and various other materials. We look forward to applying our findings toward the development of films that can be used for biomedical science, quantum devices, and other applications."