Highly sensitive sensors to measure the heart and brain activity

Electrical signals measurements such as the ECG (electrocardiogram) can show how the human brain or heart works. Next to electrical signals magnetic signals also reveal something about the activity of these organs. They could be measured with little effort and without skin contact. But the especially weak signals require highly sensitive sensors.

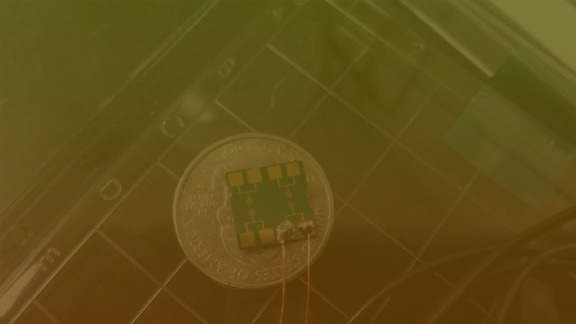

Scientists from the Collaboraive research Center 1261 "Magnetoelectric Sensors" at Kiel University have now developed a new concept for cantilever sensors, with the future aim of measuring these low frequencies of heart and brain activity. The extremely small, energy-efficient sensors are particularly well-suited for medical applications or mobile microelectronics. This is made possible by the use of electrets. Such material is permanently electrically charged, and is also used in microphones for hearing aids or mobile phones. The research team presented its sensor concept in a special edition of the renowned journal Nano Energy.

Even more effective: converting mechanical energy into electrical energy

The research team led by Professor Rainer Adelung, working group "functional nanomaterials," and Professor Franz Faupel, working group of multicomponent materials, focuses on cantilever sensors. These consist of a thin silicon strip, which in the simplest case has two layers applied: the first responds to magnetic fields (magnetostrictive material), and the second can emit an electrical voltage (piezoelectric material). "If a magnetic field occurs, the first layer deforms and thus bends the whole strip—which vibrates like a diving board at a swimming pool," explained CRC member Faupel the basic principle. Due to the deformation, the second layer emits a measurable voltage signal.

"With our new sensor concept, we searched for a way to make this conversion of mechanical energy into electrical energy even more effective, by giving the bending beam more impetus," explained doctoral researcher Marleen Schweichel. The more the bending beam vibrates, the stronger the emitted electrical signal.

Hard material made to vibrate

Normally, so-called soft materials such as plastics vibrate at a low frequency. The vibration is thus significantly damped, and the emitted signal is very weak. With hard materials, significant damping can be avoided. However, a larger mass of material is required for this purpose, which can hardly fit in the small dimensions of the sensor technology. "With our approach, we were able to make a small bending beam made of hard material behave like a soft material, and vibrate at low frequencies—and what's more, at an even greater amplitude," summarised Adelung what is so special about their findings.

Electret materials: permanently electrically charged

The decisive factor was the so-called electret. The research team applied this permanently electrically charged material underneath the bending beam. Normally, the vibrating bending beam pushes back into its original position. However, due to its self-equilibrating stress, the electret pulls the bending beam in the opposite direction, and thereby magnifies the vibration of the beam—and thus the electrical signal of the sensor.

In order to be able to read this signal as accurately as possible, the research team also integrated a new approach towards noise reduction into its alternative sensor concept. With an extremely fast measurement, the individual signals can be "picked up" in between the noise, according to first author Mona Mintken from the working group "functional nanomaterials."

Sensor with integrated power supply

Thanks to the electrets used in the sensors, it's not only low frequencies which can be measured better. Similar to permanent magnets, which create their own persistent magnetic field without a power supply, electrets also create their own permanent electric field. "The electret thereby gives the sensor a built-in electrical potential. The sensor itself then requires no external power supply, and can be used for mobile applications," explained doctoral researcher Stefan Schröder. Through a cooperation agreement, he spent three months researching at the Massachusetts Institute of Technology (MIT) in the United States, in order to further improve the required special electret layers. To do so, he used the so-called iCVD (initiator chemical vapour deposition) process, which enables individual material layers to be deposited with high precision.

"The electrets work like a kind of nanogenerator, which generates electrical energy. And can do this theoretically for over twenty years," said materials scientist Faupel. "Sensors with an integrated power supply in such small sizes are also exciting for applications in the area of the Internet of Things, which connects decentralised, autonomous electronic systems," added Adelung.