The airborne filtration system charged by electrostatic

The Department of Mechanical Engineering of The Hong Kong Polytechnic University (PolyU) has recently developed an electrostatically charged nanofiber filter with multiple separator layers, which can capture pollutant particles that are below 100 nm in diameter (covering the most common airborne nano-particles and viruses). The novel nanofiber filter demonstrates better performance in terms of breathability, filtration efficiency (10 percent higher than the conventional electret microfiber filter), and shelf life (up to 90 days).

Nano-aerosols of 100 nm and below in diameter exist everywhere in urban environments, and by virtue of their small sizes, can be easily inhaled into human bodies. Most airborne viruses, from influenza to epidemic viruses like Swine Flu or SARS, are also in the size range of 100 nm. It remains a challenging mission for scientists to develop user-friendly air filter or mask for effective capture of nano-particles and to protect people from harmful airborne contaminants and viruses that may affect health.

The team led by Ir. Professor Wallace Leung Woon-Fong, Chair Professor of Innovative Products and Technologies, used and tested polyvinylidene fluoride (PVDF), a semi-crystalline thermoplastic commonly used as insulation on electrical wires, to fabricate nanofiber filters. Applying innovative technology in Corona Discharge, the team imparted electrostatic charges onto PVDF nanofiber, to induce electrical interaction with aerosols in close distance and capture the aerosols efficiently.

Comparing with other filters made with charged microfibers or uncharged fibers on the market, PolyU's novel filter have much enhanced filtration efficiency, yet without increasing pressure drop over time (higher pressure drop means a filter facing higher airflow resistance, and thus being less breathable for the mask user or reduced flow rate for a space filter). The PVDF nanofiber has proved to be stably charged, with charging effect staying for almost three months. In prior literatures on charging other nanofibers, the imparted charges usually dissipate within a day.

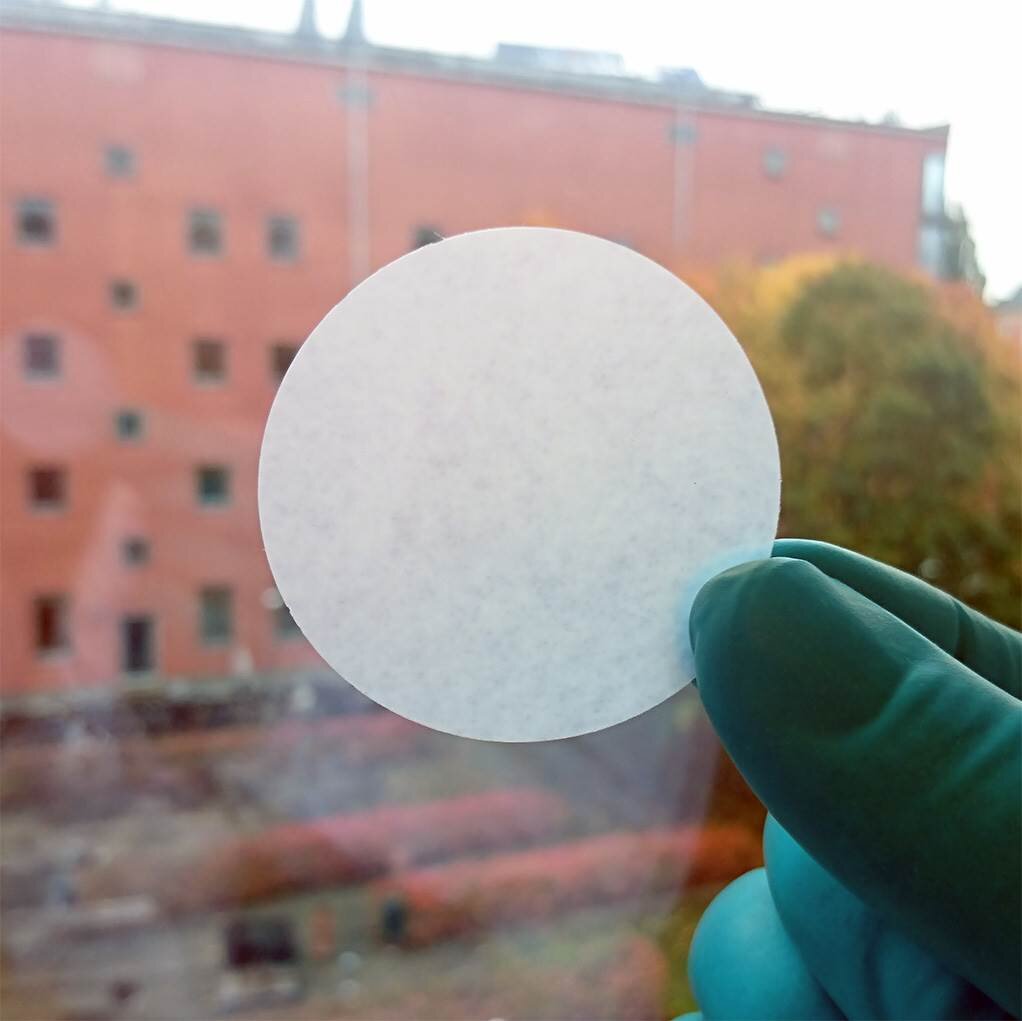

Charged PVDF nanofiber filter

In filtration tests for aerosols of various sizes conducted by the PolyU team, the charged PVDF nanofiber filter demonstrated pressure drop of only 5 Pa (Pascal / unit of pressure) and a filtration efficiency of about 54 percent for the 100 nm particle (i.e. after the air flow through the filter, 54 percent of the nano-particles of 100 nm in diameter being trapped), compared to 17 percent of non-charged PVDF nanofiber filter. There was also a 2.7 fold increase in "quality factor"—the ratio of filtration efficiency over pressure drop, or the benefit-to-cost ratio. The higher the quality factor, the better is the filter's performance taking into account the importance of both filtration and breathability.

Professor Leung said as viruses usually carry negative electrostatic charges, they can be captured very effectively by the positively charged PVDF nanofibers. "The filter or face mask applying our innovation would therefore be an ideal defense against virus during an outbreak."

Novel multiple electrostatic separator layers

To further strengthen the electrostatic capture performance of the filter, the research team developed the configuration of multiple electrostatic separator layers—distributing the same weight of PVDF nanofibers in a single-layer filter into several filter layers with each layer insulated by a separator, in order to reduce the electrostatic interference among fibers of adjacent layers and increase the filter efficiency by electrostatic force.

Filtration tests showed that filtration efficiency of the filters with charged multiple electrostatic separator layers (tests on two, three and four-layer) were 39 percent to 45 percent higher than the charged filter without the separator. Quality factor of the filters with charged multiple electrostatic separator layers were 2 to 3.5 times higher than the one without the separator.

Stability and durability

Charge on filter medium and its related electrostatic effect will dissipate with time. Filter durability test proved that PolyU's novel electrostatically charged nanofiber filter with multiple separator layers could maintain a persistently high performance for an extended period, and is thus more durable and can store for a longer time.

Filtration efficiency tests in humid ambient of 80 percent relative humidity (Hong Kong's average annual percentage of humidity is 77.0 percent) for filters with four electrostatic separator layers (with 1.75 grams of fibers per square meter) showed that the filtration efficiency dropped only marginally after 15 days, and dropped only 1 percent after 90 days.

Potential applications

PolyU's innovation can be widely applied in air filtration, from industrial to personal and household applications. Industrial usage includes dust-free rooms and fossil-fuel power stations. Air filtration can also be used to reduce particulate emission from exhaust of ships and vehicles. Personal and household usage of air filtration includes facemask, air purifier, vacuum cleaner, window filter screen, etc.

The electret PVDF nanofiber filter can be used in Western Blot, an analytical technique widely used to detect or extract proteins. In the process, PVDF membrane is often used in transferring proteins separated from the original sample. The PolyU innovation can help greatly enhance the nanofiber mat's electrostatic force in capturing protein, while maintaining the protein integrity without affecting its organization.

The innovation can also be applied to effective release of protein-based drugs. Drugs made in powder form, for example asthma drug, can be captured electrostatically by the charged PVDF nanofiber mat for more effective release and inhalation by users. Other than drugs delivered by inhalation, the innovation can also be applied similarly to drugs for use topically over skin.