Microlasers for photonic computing of future can be produced today quickly and cheaply

Scientists of the Far Eastern Federal University (FEFU) together with Russian colleagues from ITMO University, researchers at the University of Texas at Dallas, and Australian National University have developed an efficient, fast and cheap way to produce perovskite microdisk lasers—sources of intense coherent radiation for optical microchips to be used in new-generation optical computers. The related article was published in ACS Nano.

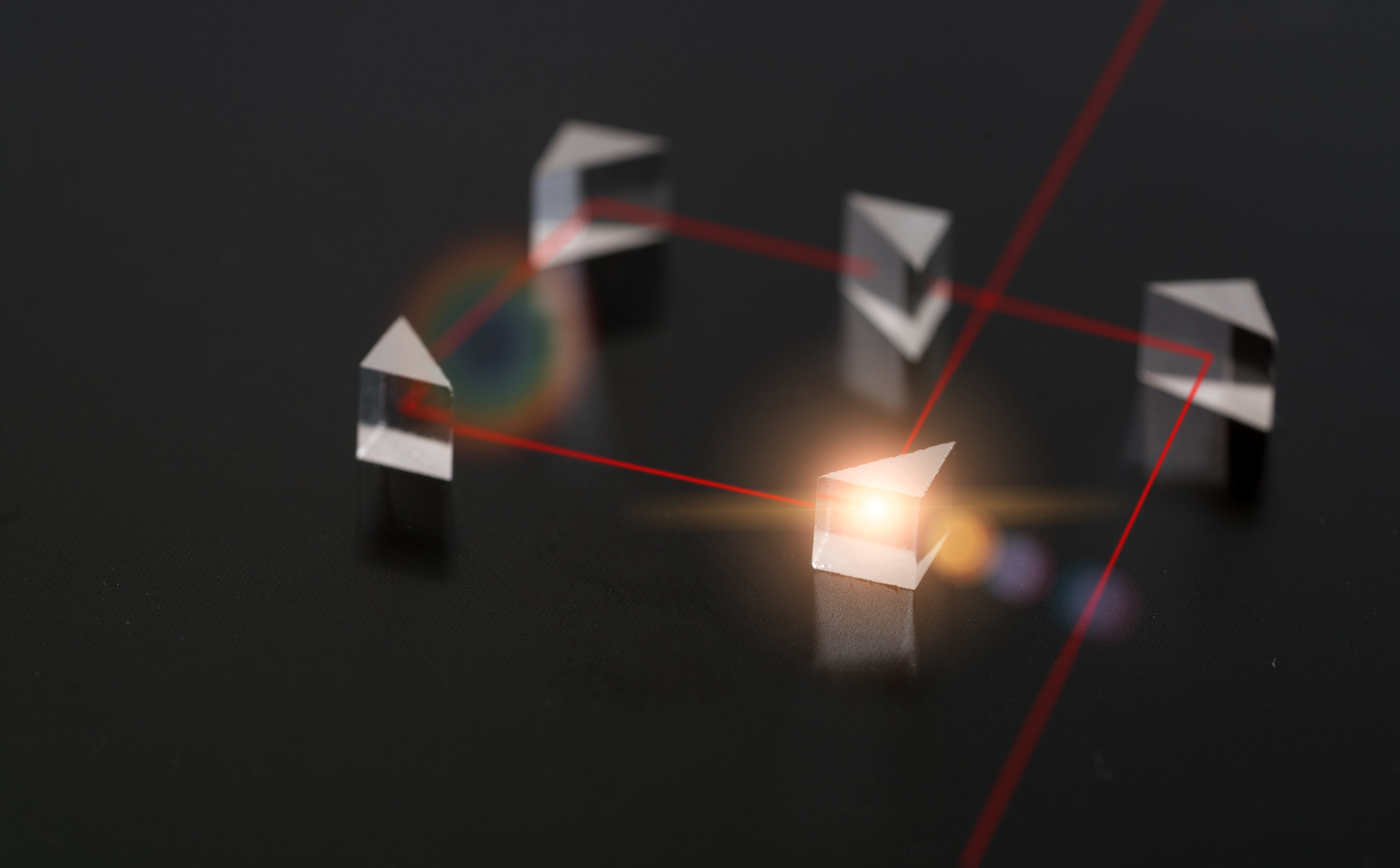

Using ultrashort laser pulses, scientists printed optical microdisk lasers in thin perovskite films coated above a glass substrate. The produced perovskite lasers can be used in photonic computers of the future and more widely—to provide the operation of photonic circuits in ultrafast data processing systems.

"We used femtosecond laser pulses with a specially designed donut-shaped intensity profile. The direct impact of a low-intense pulse train on a thin halide perovskite film allows to imprint the disks with a diameter down to 2 microns. The imprinted disks have smooth facets while the femtosecond pulse processing ensures minimized thermal impact of the perovskite material within the disks, which is extremely important for the subsequent stable operation of the produced laser. Our original laser printing technology provides a simple, cost-effective and highly controllable way for mass production of various perovskite microdisk lasers. Importantly, the optimization of the microdisk geometry in the process of laser printing allows for the first time to achieve stable single-mode lasing with perovskite microlaser. Such lasers are promising for creating various optoelectronic and nanophotonic devices, sensors, etc." Explained Alexey Zhizhchenko, the research associate of the FEFU center for Virtual and Augmented reality.

Perovskite microlasers are characterized by impressive performance, easy handling, and room temperature operation. However, until today, their widespread implementation was a bit challenging. The problem was the lack of efficient and low-cost fabrication methods. For example, chemical synthesis doesn't guarantee the equal size and output characteristics of the produced perovskite structures requiring to use expensive lithography-fabricated templates. Moreover, the characteristics of the previously designed perovskite microlasers prohibited their single-mode operation. The novel method of laser printing of perovskite microdiscs developed by FEFU and ITMO University scientists in close cooperation with foreign colleagues removes this limitation. It allows one to easily produce stable laser light sources with predetermined, controlled parameters. The technique can be implemented in the industry in the near future.

"Achievements of the researchers of the FEFU Center for Virtual and Augmented reality become possible due to the realization of "Materials" priority project. We managed to assemble an active international team of world-class specialists, much of which is young scientists under 30 years old." Notes Kirill Golokhvast, FEFU Vice-Rector for Research.

"Conducting laser studies of such a high level has become possible thanks to the new femtosecond laser lithograph setup installed at FEFU as well as the close cooperation of the FEFU and ITMO University teams," went on Golokhvast.