Isolated carbon nanotubes show clear advantage

The small dimensions, optical and electronic properties, and flexibility of single-walled carbon nanotubes (SWCNTs) make them ideal candidates for transparent conductive films in touch screens, smart windows, photovoltaic cells, and other devices. But when SWCNTs aggregate and become bundled together, Schottky junctions form between the nanotubes that downgrade their optoelectronic properties.

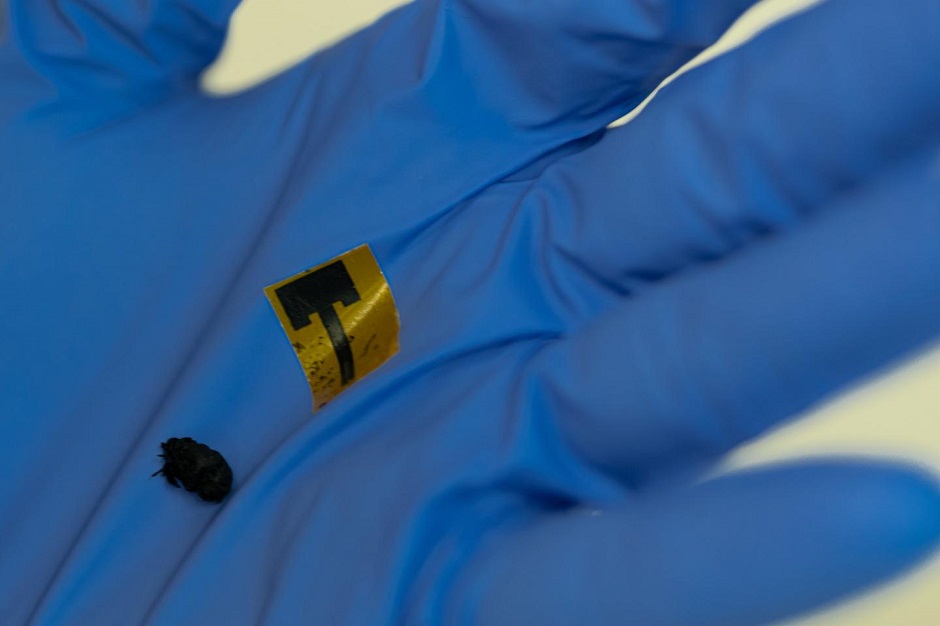

Now, however, researchers have created a network of isolated, individual nanotubes that avoid these issues [Jiang et al., Sci. Adv. 4 (2018) eaap9264]. Thin films made from SWCNTs show transmittance of 90% and a record low sheet resistance, over five times lower than previously reported. Moreover, simple treatment with HNO3 reduces the sheet resistance still further, to a level on a par with conventional indium tin oxide (ITO).

“Our SWCNT films are mainly composed of isolated SWCNTs, which is quite different from usual SWCNT films made up of bundles with diameters of tens of nanometers,” says Hui-Ming Cheng of the Institute of Metal Research, Chinese Academy of Science, in Shenyang.

The team from ShanghaiTech University, Shanghai Institute of Microsystem and Information Technology, University of Chinese Academy of Sciences, University of Science and Technology of China, Changchun Institute of Applied Chemistry, Tsinghua University, and Aalto University School of Science in Finland used a floating catalyst chemical vapor deposition method to synthesize high-quality SWCNTs, which are subsequently collected on a porous substrate that acts like a filter.

“By tuning the nucleation and growth concentration of SWCNTs, 85% of are isolated,” explains Cheng. “Meanwhile, by controlling the content of the carbon source, a ‘carbon welded’ structure is formed at tube-tube junctions.”

The researchers believe that the isolated nanotubes maximize the transmittance of light, while the fact that the intersections are welded together with graphitic carbon – instead of forming Schottky junctions – minimizes electrical resistance.

“SWCNTs usually aggregate into bundles via van der Waals interactions and, as a result, the internal tubes absorb light while contributing little to carrier transport,” points out Cheng. “Meanwhile, Schottky barriers at intertube junctions suppress carrier transport, which resulting in much higher junction resistance.”

The improved SWCNT film enables the fabrication of organic light-emitting diodes (OLEDs) with very low turn-on voltages (2.5 V) and very high current efficiency (75 cd A−1).

“We have demonstrated that OLEDs constructed with our SWCNT films as the anode show a current efficiency 7.5 times higher than that of the best reported CNT anode-based OLEDs and also exhibit excellent flexibility and stability,” says Cheng. “Compared to ITO, our SWCNT films show comparable transparent conductive performance but much better flexibility.”

Andrew Rinzler of the University of Florida comments:

“In the competitive landscape of transparent electrodes, ITO remains difficult to beat; except, however, in flexible electronics where given ITO’s brittleness and the oxidation that plagues silver nanowires, transparent SWCNT films remain the best option. This is very impressive performance for transparent conductive SWCNT films. Indeed, it is the best performance for such films that I have seen,” he adds.

The researchers believe that the isolated SWCNT thin films could be useful as transparent electrodes in many flexible electronic and optoelectronic devices. Flexible touch screens and OLED displays could be using the new SWCNT films in several years’ time, suggests Cheng.

“It is exciting to see a strategy of carbon-welding to decrease the junction resistance between nanotubes, resulting record performance of optical transmittance versus sheet resistance for transparent conducting electrodes. Although further development is still needed, the work here opens up opportunities for flexible optoelectronic devices,” says Yi Cui of Stanford University.

Moving towards commercial production will require an increase in the yield of SWCNTs without losing the crucial isolation. The team is now working on this issue, as well as introducing control over the nanotube type and length. However, Rinzler is cautions that because growing individual nanotubes requires a low concentration of catalyst nuclei, scaling up the process may not be so simple.