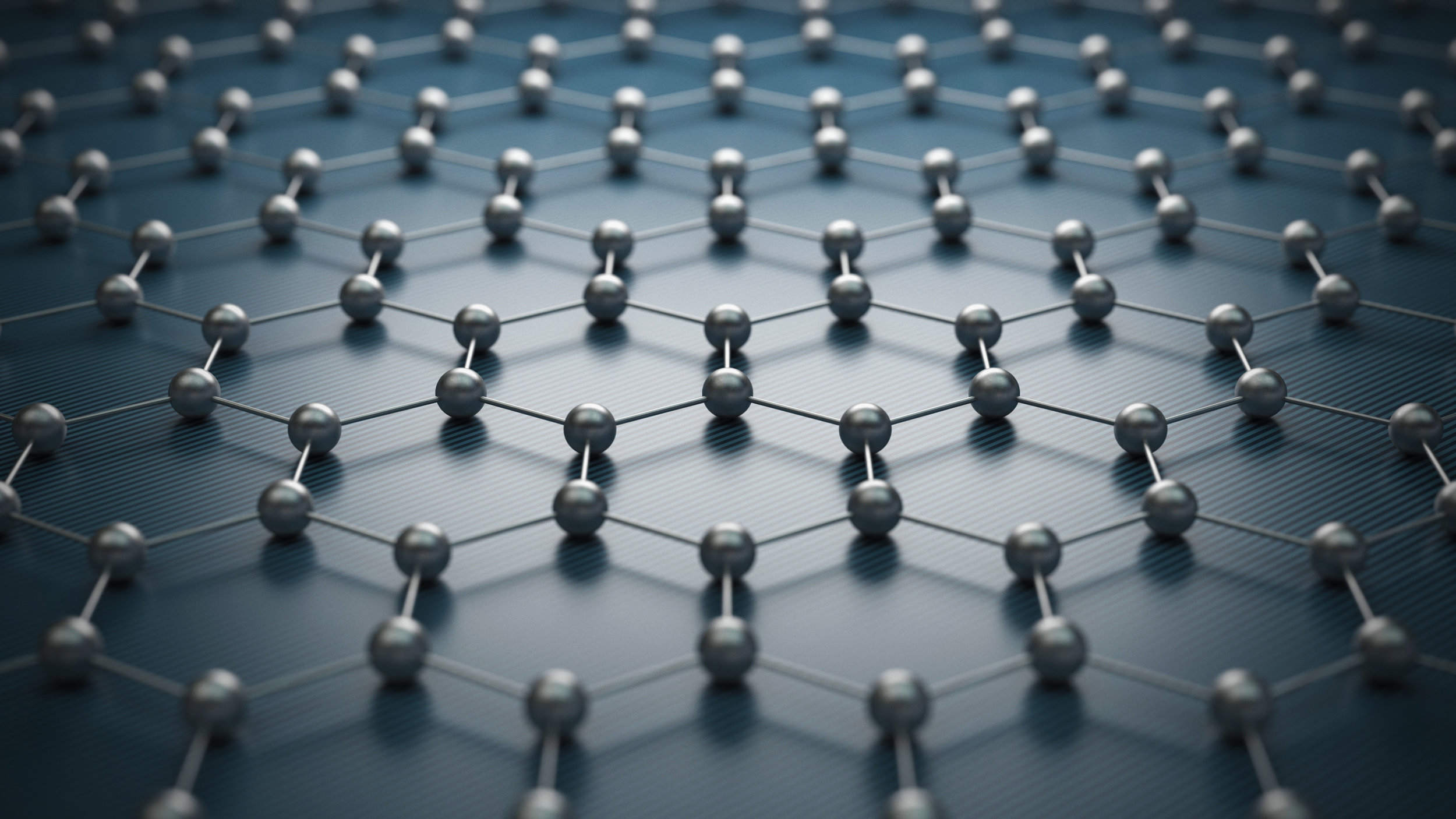

Researcher develops a new generation of graphene

The material graphene has many incredible properties, but to date it has been difficult to use on a large scale in industry, because it loses its unique properties and goes back to its origin graphite. Researcher Mamoun Taher has developed a new form of graphene that can solve the problem.

“The challenge has been to scale up graphene’s outstanding properties from nanoscale at laboratories to macro-scale at industry without degradation,” says Mamoun Taher. He is a researcher at the Department of Chemistry at Uppsala University and CEO of start-up company Graphmatech.

Graphene is one atom thick two-dimensional carbon material. It is flexible, 200 times stronger than steel, and has many other advantageous properties. The problem is that when it is produced on a large scale, the thin flakes have tendency to re-stick. As a result, the material loses its wonder properties and becomes more like graphite.

The new material, Aros Graphene, has been designed to prevent this by incorporating designed molecules, so called “separators”.

“The separators are designed to separate graphene flakes without degrading their properties, so we have control over the material. The process has been designed to be environmentally accepted, we use water as a solvent and no hazardous chemicals.”

Research in collaboration with companies

Mamoun Taher splits his time between research at the Ångström Laboratory and working with start-up company Graphmatech. By his side is entrepreneur Björn Lind, one of the brains behind the company Disruptive Materials and Upsalite, another material developed from research at Uppsala University.

The development takes place in close partnership with the company ABB and they also have access to ABB’s laboratories in Västerås.

Mamoun Taher made his discovery as a postdoc at Uppsala University. Originally from Syria, after he wrote a doctoral dissertation in the chemistry of interfaces at Luleå University of Technology, he came to Uppsala University. In collaboration with ABB Corporate Research Center in Västerås, he worked with graphene materials, but was struck by how much of the properties were lost when the flakes stuck together.

“I combined my previous research with my studies of graphene, and that’s how Aros Graphene was born.”

Thermal management of electronics

He contacted UU Innovation, the University´s unit for support for commercialisation of research results, and the European organisation InnoEnergy. With their support, the company took off. There are applications in electronics and telecommunication industry, where the material can be used to efficiently dissipate heat from electronics which enables more compacted designs, longer life spam and safer operation.

“We’ve seen that a thermal paste that contains Aros Graphene is 180 percent more thermally conductive than other thermal paste products on the market. In the close future where more and more data centres will be needed to store data, there is huge demand for advanced thermal management solutions.”

GraphMaTech has several other projects, for example on self-lubricating mechanical systems, 3D printing, moving electrical contacts and printed supercapacitors.

“We aren’t just developing a material, but also processes that can be used by graphene producers and other materials-related industries. We’re currently in discussions about licensing our process,” says Mamoun Taher.